ScreensPacking

The procedure

ScreensPacking(Fluid$, m_dot, d, m, A_fr, L, T_i, T_o, P, Cor: h, DELTAp, A_s, DELTAp_c, alpha, phi, sigma, f, j_H)

returns the flow-side behavior of a randomly stacked array of woven screens.

Inputs:

Fluid$ - string variable indicating a specific fluid in EES database

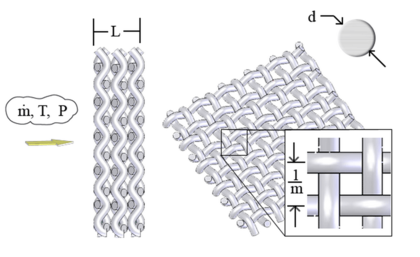

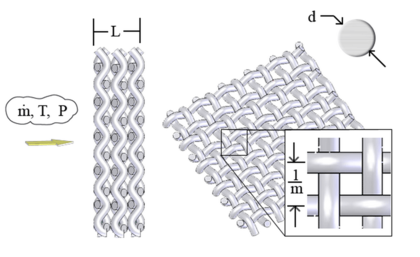

m_dot - mass flow rate of fluid [kg/s] or [lbm/min]

d - diameter of wire comprising screen [m] or [ft]

m - the number of mesh openings per unit length [1/m] or [1/ft]

A_fr - the frontal area of the screen exposed to fluid flow [m^2] or [ft^2]

L - length/depth of stacked screens [m] or [ft]

T_i - inlet temperature of the fluid [C], [K], [F], [R]

T_o- outlet temperature of the fluid [C], [K], [F], [R]

P - pressure of the fluid at the inlet [Pa], [kPa], [bar], [MPa], [atm], or [psia]

Cor - correlation to use, (1 = Kays & London, 2 = Gedeon and Wood)

Ouputs:

h - heat transfer coefficient [W/m^2-K] or [Btu/hr-ft^2-R]

DELTAp = total pressure drop [Pa], [kPa], [bar], [MPa], [atm], or [psia]

A_s = surface area [m^2] or [ft^2]

DELTAp_c = core-only pressure drop [Pa], [kPa], [bar], [MPa], [atm], or [psia]

alpha = surface area for heat transfer per volume [m^2/m^3] or [ft^2/ft^3]

phi = porosity [-]

sigma = flow area/frontal area [-]

f - friction factor [-]

j_H = Stanton j-factor [-]

Notes: This function determines the fluid properties at the average pressure and temperature, and the Reynold's number from the screen mesh and wire diameter. In order to determine the Reynold's number, the porosity is needed. The idealized equations relating the screen mesh and diameter to porosity were based on those provided on page 52 of Ackermann (1997). With the Reynold's number and porosity calculated, the non-dimensional function Screens_ND is called to determine the values for the Colburn j and friction factor using either the correlation selected. The Colburn j factor is interpreted by Screens and returned as a heat transfer coefficient. It is assumed that the screens are perfectly arranged, i.e. the thickness of a single screen is exactly twice the wire diameter, and there is no gap between successive screens. The core pressure drop is determined based on frictional considerations. Pressure drop due to fluid acceleration and expansion/contraction are included in DELTAp but not in DELTAp_c.

Example:

$UnitSystem SI Mass J K Pa Radian

$VarInfo alpha units=m^2/m^3

$VarInfo A_s units=m^2

$VarInfo DELTAp units=Pa

$VarInfo DELTAp_c units=Pa

$VarInfo h units=W/m^2-K

$VarInfo m units=1/m

Fluid$='air'

m_dot=0.1 [kg/s]

d=0.002 [m]

m=1/0.004 [m]

A_fr=0.01 [m^2]

L=0.01 [m]

T_i=300 [K]

T_o=320 [K]

P=1e6 [Pa]

Cor=2

Call screenspacking(Fluid$, m_dot, d, m, A_fr, L, T_i, T_o, P, Cor: h, DELTAp, A_s, DELTAp_c, alpha, phi, sigma, f, j_H)

{Solution:

h = 528.7 [W/m^2-K]

DELTAp = 128.1 [Pa]

A_s = 0.07854 [m^2]

DELTAp_c = 127.3 [Pa]

alpha = 785.4 [m^2/m^3]

phi = 0.6073 [-]

sigma = 0.25 [-]

f = 0.3358 [-]

j_H = 0.02571 [-]

}